Equalizer’s Secure Grip Spreaders In Action

02/21/2013 in Equalizer International, Flange Spreaders, Maintenance

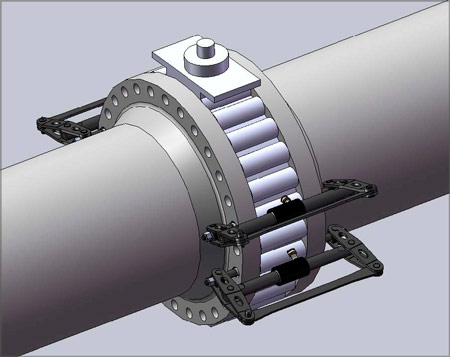

With the introduction of the Secure Grip Line of flange spreaders, Equalizer International raised the bar for safety and operator friendliness beyond the reach of the competition. Developed in response to a request by the Vector Group to support their SPO compact Zero Gap flange line, the Secure Grip Spreader separates the flanges by gripping the inside of the bolt hole using Equalizer’s patented collet technology.

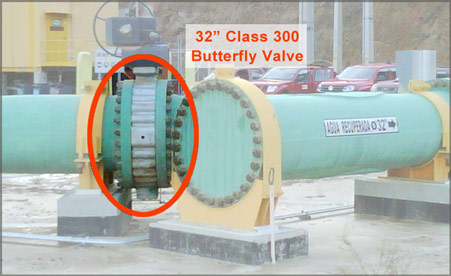

Although it was Vector’s innovative SPO compact flange that gave rise to the Secure Grip flange spreaders, the design is being used to separate any type of flange, particularly if the job calls for a very powerful tool. In late 2012, working with our partner Morken Chile, the Secure Grip flange spreaders were used by a global Chilean mining company to remove and service butterfly valves.

The applicable tool for the flanges specified is the SG15TE fitted with M48 1-7/8” collets.

The standard stroke from an SG15TE is 0-4 inches (0-100mm), however the specified valve has a thickness of 10 inches (246mm). Therefore, with Equalizer's engineered modifications, increased the stroke to 14 inches (255mm).

The 32” ANSI 300 flanges are on a pipeline critical to production, so it was essential that the time to change out the valve be kept to a minimum. The operator ‘s interest was in the time saving, but it was the safety benefits that closed the sale. When working with flanges of this size safety becomes a multifaceted concern, since without this technology the job would require a mix of heavy machinery and personnel working together under stresses and strains that increase the exposure and probability of an accident.

The job was scheduled for 12 hours by maintenance and was completed by the operators in 45 minutes! The installation and operation of the tool is excellently demonstrated in the latest video posted by Equalizer International to Youtube.