Pipeline Field Maintenance, Repairs, Pipeline Reinforcements

Enerteq offers the pipeline integrity alternative suited to your situation.

Enerteq and its industry partners can provide your company with the field products and services for pipeline repair and maintenance.

Enerteq and its industry partners can provide your company with the field products and services for pipeline repair and maintenance.

Whether the need is for a quick repair using steel for pipewall reinforcement, or for interventions, such as hot tapping and line stopping projects, we provide industry compliant solutions in accordance with ASME, ANSI & API standards.

We provide full and partial encirclement steel clamps and sleeves, using the latest technologies to return the pipe to its original pressure rating.

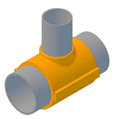

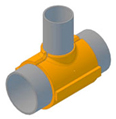

Full-Encirclement Reinforcing Saddles are used to provide reinforcement for branch outlets in accordance with ASME B31.3, B31.4, B31.8 and other applicable design codes.

When only partial reinforcement is required we can provide partial saddles in accordance with ASME B31.3, B31.4

Manufactured in compliance with ISO 9001:2008 certified quality program

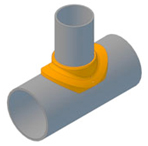

Extruded Branch Outlets & Manifolds

Produced from a variety of metals, including: carbon, stainless and high alloy steels.

Full-Encirclement Reinforcing Saddles

Full encirclement saddles manufactured to meet most needs. Full-Encirclement Reinforcing Saddles with full size or reduced branch outlets.

Full-Encirclement Saddles are stocked in a variety of sizes and configurations manufactured using A234 Grade WPB material. We also have the in-house capability to supply stainless or high-yield stress saddles in any size or configuration required.

Single or two piece construction and split in any of five configurations:

|

|

|

|

Part 1 — Single piece construction, split into two equal halves through the run and the branch |

Part 2 — Single piece construction, split longitudinally through the run perpendicular to the branch | Part 3 — Two piece construction, composed of a run cylinder welded to a partial saddle, split into two equal halves through the run and the branch |

|

|

|

| Part 4 — Two piece construction, composed of a run cylinder welded to a partial saddle, split longitudinally through the run perpendicular to the branch | Part 5 — Single piece construction, cut into three sections by splitting through the branch and through the run perpendicular to the branch |

With a number of combinations of run and branch sizes are stocked and ready for immediate shipment. Our standard saddles are manufactured from Grade WPB material, but we also have the in-house capability to supply stainless or high-yield stress saddles in any size if required.

With a number of combinations of run and branch sizes are stocked and ready for immediate shipment. Our standard saddles are manufactured from Grade WPB material, but we also have the in-house capability to supply stainless or high-yield stress saddles in any size if required.

Used to repair and reinforce pipelines damaged due to internal and external corrosion, gouges, dents, cracks and defective welds. Our manufacturer produces Pipeline Reinforcing Sleeves for non-pressure retaining structural reinforcement or for applications where the sleeve will be required to contain the full design pressure of the pipeline. Pipeline Reinforcing Sleeves are custom fabricated to the unique design requirements of each situation.

Extruded branch outlets that produce single and multiple headers and manifolds. Design allows greater flexibility though reinforcement at the extruded neck. Header branch welds are eliminated, reducing issues with radiograph inspections. Less costly to produce.

Extruded branch outlets that produce single and multiple headers and manifolds. Design allows greater flexibility though reinforcement at the extruded neck. Header branch welds are eliminated, reducing issues with radiograph inspections. Less costly to produce.

Produced from a variety of metals, including: carbon, stainless and high alloy steels.