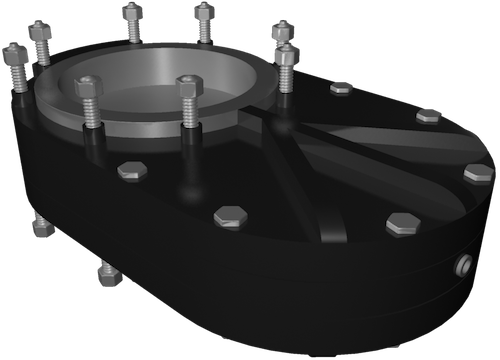

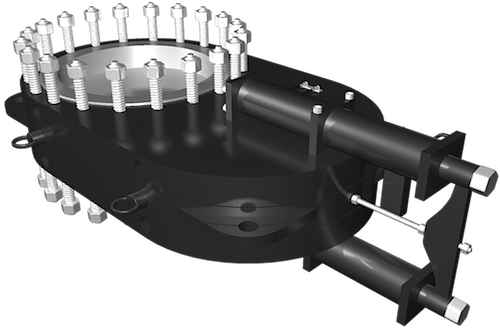

Slim Valves (AKA Sandwich Valves)

Are known also by Sandwich valves (T.D.Williamson) are used to control the hottap and LineStop operations. They are gate valve type and have specially reduced face to face distance in order to make easier the Hottap & LineStop Intervention. We have a wide range of dimensions, class and material of Slim Valves. We cover 150# to 900#.

100% compatible with TDW equipment

Slim Valves are manufactured according to the European and American codes and standards.

Slim Valves are manufactured as:

- Sizes: 2" to 56"

- Rating: 150#, 300#, 600# and 900#

- design Pressure: up to 2500 PSI

- Manual or Hydrauliclly Operated

- Maximum Operating Temperature 180 ºF – 82 ºC

- Test Pressure 1.5 X Design Pressure per ASME

- Hydraulic and Functional test under pressure.

- High Strength steel (ASTM A 516 Gr 60/URSSA 690/ S355 J2+N)

- Nitrile/Viton O rings (under request)

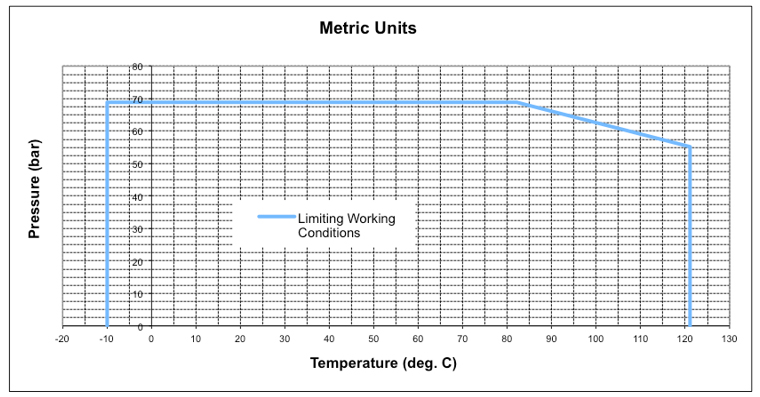

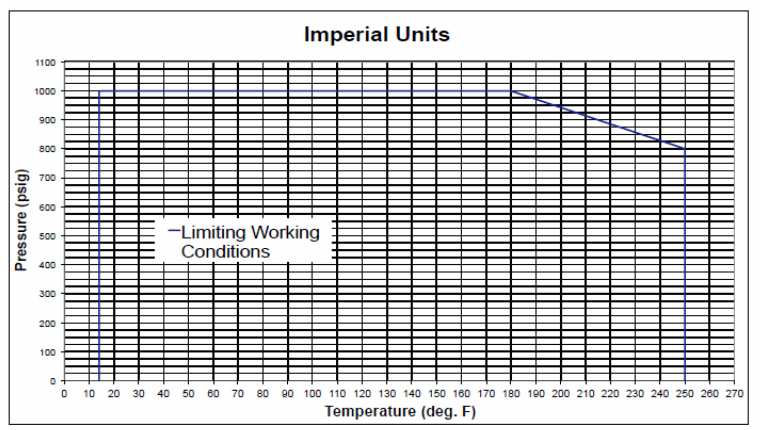

MAXIMUM WORKING LIMITS

The maximum working limits of the valve are defined by two points: a maximum working pressure at a specified temperature and a maximum working temperature at a specified (lower) pressure. It is acceptable to operate the valve at any pressure up to a limit defined by a straight line drawn between the above limiting points on a pressure temperature diagram. The safe working limits for pressure and temperature are illustrated graphically in figures 2 and 3. It is the end user’s responsibility to ensure that the valve is not attached to a system whose operating conditions exceed the Maximum Working Pressure and the Maximum Working Temperature specified above. The valve has not over pressure protection system of its own, so the setting of the safety / relief valve(s) protecting the line to which it is attached must not exceed the working pressure at the appropriate maximum working temperature.